Ģ019: The production unit in Gimo, Sweden, is officially announced as a "lighthouse" by World Economic Forum as a role model in industry 4.0. Ģ017: PrimeTurning is introduced, a new methodology enabling turning in all directions. Ģ016: CoroPlus makes its first appearance, used in the design, planning, monitoring of machining performance and the optimization of machining processes. Ģ013: Sandvik Coromant researchers discover that it is possible to control coating crystals at an atomic level to create uniform, tightly-packed, thermal-protected coating for new levels of hardness: Inveio coating technology is introduced. The unique Silent Tools damping adaptors allow for increased cutting parameters and a more secure, vibration-free process. Ģ008: Sandvik Coromant acquires Norwegian anti-vibration tool developer Teeness. ġ997: Sandvik Coromant offers to repurchase used cemented carbide inserts for recycling, underlining the company's commitment to environmental responsibility.

#COROMANT CAPTO ISO#

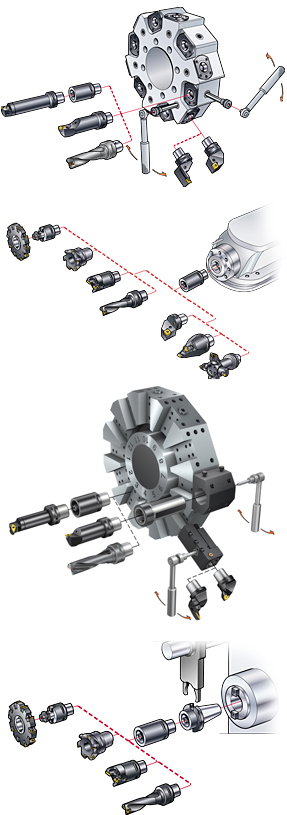

Today Coromant Capto (Latin for “I am gripping”) is an established system and an ISO standard around the world. This ground-breaking invention provided a new and efficient means of combining and organizing tooling, while reducing tool-changing time in machinery. ġ990: Coromant Capto, a single holding system for both rotating and stationary spindles, is introduced. Tool-pool, machine-adapted tool recommendations and mini-catalogues are made available. ġ972: The Multi-Service marketing campaign sees the light of day, and the yellow coat becomes an important symbol. ġ969: Heat-resistant Gamma Coating, or GC, is introduced as a grade, revolutionizing turning, milling, and drilling with previously unmatched metal cutting performance. The birth of the T-Max holder and use of indexable inserts is the start of a big change in the practice and productivity in machining. However, in 1951, new innovations and manufacturing methods lead to the establishment of a more industrialized unit in Gimo, Sweden.ġ957: Scrapers become the first product with mechanically clamped “indexable inserts” or “throw-away inserts”.

#COROMANT CAPTO SOFTWARE#

Digital machining, including advanced software and tools that support digital manufacturing, from design and planning to machining and machining analysis.ġ942: The company began as a small production unit for cemented carbide tools in Sandviken, Sweden when Wilhelm Haglund is assigned the job as manager of the unit.Tool holding, including tools for turning centres and lathe tools, machining centres, multi-task machines and sliding head machines.Boring, including rough boring, fine boring and reaming.Drilling, including general drilling, step and chamfer drilling, composite drilling and tapping.Milling, including face milling, shoulder milling, profile milling, turn milling, high feed milling, chamfering, slot milling and thread milling.Turning, including general turning, heavy turning, small part machining, parting and grooving, hard part turning and threading.Sandvik Coromant produces an extensive range of metal cutting tools:

It is part of the business area Sandvik Machining Solutions within the global industrial group Sandvik. Sandvik Coromant is headquartered in Sandviken, Sweden and is represented in more than 150 countries with some 7900 employees worldwide. Sandvik Coromant is a Swedish company that supplies cutting tools and services to the metal cutting industry.

0 kommentar(er)

0 kommentar(er)